ElectraLith’s Subsequent-Technology DLE-R Know-how Produces Battery Grade Lithium Hydroxide from Salar Brines, Geothermal Oilfield Brines and Spodumene Leach

Melbourne, Victoria, twenty second August 2024, ZEX PR WIRE, Melbourne-based ElectraLith Pty Ltd (“ElectraLith”) at present introduced that its next-generation DLE-R expertise has efficiently produced battery grade lithium hydroxide from salar brines, geothermal oilfield brines and spodumene leach utilizing its proprietary DLE-R expertise.

Picture: ElectraLith’s DLE-R

This included manufacturing of 99.9% pure lithium hydroxide from a contaminated brine comprising lower than 60 components per million (“ppm”) lithium. The proof of idea was achieved utilizing no water, no chemical compounds and minimal power.

DLE-R is a proprietary end-to-end electro-membrane expertise. Not like most Direct Lithium Extraction (“DLE”) applied sciences which typically produce lithium chloride, DLE-R can produce battery grade lithium hydroxide or lithium carbonate as its closing product.

DLE-R makes use of no water or chemical compounds and may run completely on renewable energy, delivering a step-change discount to the environmental and financial prices of different lithium extraction processes.

“Our production of battery grade lithium hydroxide from a range of sources provides proof of concept and continues our progress towards commercialisation,” stated ElectraLith CEO Charlie McGill.

“These test results validate the true potential of DLE-R across lithium resource type, quality and concentration, underpinning DLE-R’s emergence as the most economic and sustainable method for extracting and refining lithium.”

Pushed by EV demand, the worldwide lithium market is projected to develop from USD 27 billion in 2024 to USD 134 billion by 2032 at a CAGR of twenty-two%.

ElectraLith’s patented DLE-stage membranes are based mostly on revolutionary work performed by world-renowned membrane scientist Sir John Monash Professor Laureate Huanting Wang of Monash College.

Professor Wang is chair of ElectraLith’s Science Advisory Committee and is without doubt one of the world’s most cited nanomaterials researchers.

Spun out of Monash College and backed by Rio Tinto and IP Group, ElectraLith is rising because the cleanest, most versatile and most cost-efficient technique for extracting and refining lithium, the basic component of driving a sustainable future.

About DLE-R

DLE-R contains two levels:

-

DLE-stage: Proprietary membranes extract lithium utilizing electrodialysis to provide lithium chloride. The DLE-stage distinguishes itself from different DLE processes by eliminating water and chemical compounds; it’s additional distinguished by its potential to extract lithium from any supply, together with contaminated brines of extraordinarily low focus.

-

R-stage: Comparable electrodialysis ideas convert the lithium chloride into lithium hydroxide utilizing off-the-shelf expertise in a proprietary configuration. If required, the ensuing lithium hydroxide can then be transformed to lithium carbonate utilizing a novel carbon-negative technique.

Each levels are designed to function completely utilizing electrodialysis, a commercially confirmed expertise that has been deployed worldwide because the Fifties.

Proof of Idea

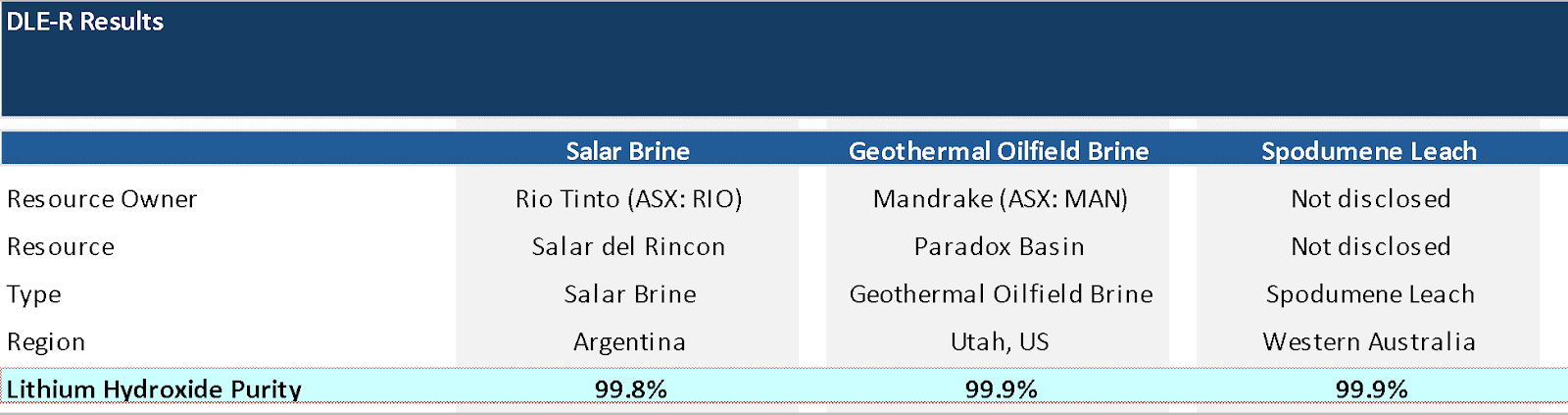

Validating these ideas, DLE-R produced battery grade lithium hydroxide from a variety of lithium sources (salar brines, geothermal oilfield brines, spodumene leach) and geographies (US, Argentina and Australia) utilizing no water, no chemical compounds and minimal power.

This proof of idea included manufacturing of 99.9% pure lithium hydroxide from a contaminated brine comprising lower than 60ppm lithium.

Picture: DLE-R outcomes

ElectraLith CEO Charlie McGill stated: “We’re particularly excited about the Paradox Basin Utah result, where DLE-R produced 99.9% pure lithium hydroxide from Mandrake’s geothermal oilfield brines without water, an increasingly scarce resource in the broader Colorado River Basin. This, coupled with the production of lithium hydroxide from a brine with less than 60ppm, demonstrates DLE-R’s ability to unlock otherwise unviable strategic reserves in the United States and Australia.”

Mandrake CEO James Allchurch commented: “The outstanding performance of the DLE-R process is a critical step forward for Mandrake as we seek to commercialise our expansive Utah Lithium Project. DLE-R is perfectly suited to the water chemistry of the Paradox Basin and we look forward to partnering with ElectraLith in processing larger volumes of brine from the Utah Lithium Project.”

Technoeconomics

DLE-R’s proof of idea coincides with the supply of a Technoeconomic Evaluation Report performed by Worley Consulting Pty Ltd (“Worley”). This American Affiliation of Price Engineers (“AACE”) Class 5 report follows an eight-month assessment leveraging Worley’s world experience within the US, Canada and Australia, in addition to enter from Rio Tinto.

DLE-R’s proof of idea additionally coincides with the supply of a Course of Mannequin carried out by Dr Mike Dry of Arithmetek Inc., a globally recognised knowledgeable within the area of course of and early-stage value modelling, in addition to a Life Cycle Evaluation (LCA) carried out by Minviro. Minviro is a worldwide sustainability and LCA authority with workplaces within the UK, Australia and China.

IP Group Australia Managing Director and ElectraLith Chair Mike Molinari commented: “These reports provide an important validation of ElectraLith’s revolutionary DLE-R process. As we enter the prototyping stage, our relationships with these world-class consultants will be vital to delivering on DLE-R’s potential to reshape the lithium industry.”

Rio Tinto Chief Advisor for Battery Minerals and ElectraLith Non-Govt Director Travis Baroni stated: “We invested in ElectraLith to support their DLE-R technology and we are pleased that it is showing real potential to significantly reduce the economic and environmental costs of lithium production. We’re looking forward to trialling and testing the first DLE-R prototype at our Rincon Project in Argentina with the ElectraLith team.”

About ElectraLith

ElectraLith is unlocking a inexperienced future with the cleanest, quickest and most effective technique of extracting and refining lithium, the first component of a sustainable future. ElectraLith’s cutting-edge DLE-R expertise revolutionises t5he DLE and refining processes by extracting and producing battery-grade lithium hydroxide in a single, scalable and modular step. Versus different DLE processes, DLE-R absolutely eliminates the necessity for water and chemical compounds and may run completely on renewable power. Backed by Rio Tinto, IP Group Australia and Monash College, ElectraLith is predicated in Melbourne, Australia.

https://www.electralith.com.

https://www.youtube.com/watch?v=yvP9po-A6Uw

About Rio Tinto

Based in 1873, Rio Tinto is a number one world mining and metals firm devoted to discovering, mining, and processing the Earth’s mineral sources. Rio Tinto’s various portfolio contains lithium, aluminium, copper, diamonds, gold, industrial minerals, iron ore, and uranium. Rio Tinto operates beneath a twin listed firms (DLC) construction and is listed as Rio Tinto Restricted on the Australian Inventory Change (ASX) and as Rio Tinto PLC on the London Inventory Change

https://www.riotinto.com/

About IP Group

IP Group develops world-changing science and expertise companies throughout life sciences, expertise and cleantech. The Group has a robust observe document of success, having been the founder investor in plenty of high-profile firms together with Oxford Nanopore Applied sciences plc. In Australia and New Zealand, IP Group works in shut partnership with the Go8 Universities and the College of Auckland to determine ground-breaking applied sciences rooted in onerous science, which have probably the most promising industrial potential. IP Group is listed on the Most important Market of the London Inventory Change beneath the code IPO.

http://www.ipgroupanz.com

About Mandrake

Mandrake is an ASX-listed explorer that’s advancing its large-scale lithium venture in Utah’s Paradox Basin. The Firm’s lithium enterprise spans a land space exceeding 93,000 acres (~379km2).

Mandrake has made vital progress in compiling geological and petrophysical knowledge which has allowed it to provide a major Exploration Goal (JORC 2012) for Lithium mineralisation which ranges from 1.7 to five.6 million tonnes of contained Lithium Carbonate Equal (LCE) and is now focusing the exploration efforts in direction of establishing a maiden Mineral Useful resource within the close to future.

https://www.mandrakeresources.com.au/